Excimer lamps utilize light (excimer light) generated by discharge plasma in a lamp filled with a rare gas.

Major wavelengths include 126 nm (Ar2), 146 nm (Kr2), 172 nm (Xe2), 222 nm (KrCl), and 308 nm (XeCl).

We use lamp units manufactured by Hamamatsu Photonics Co., Ltd. with a main wavelength of 172 nm using Xe2, and provide equipment for surface modification and hydrophilic treatment processing (wettability improvement) applications.

Features of excimer lamps

- Uniform irradiation over a large area is made possible by the use of flat lamps.

- Stable output with less flickering by adopting RF (Radio Frequency)

- Single wavelength of 172nm enables effective excimer irradiation treatment.

- Possible to turn the light on and off instantly.

Features of excimer irradiation treatment

- Unlike corona discharge and plasma methods, which irradiate materials directly with electric discharges, excimer irradiation only irradiates vacuum ultraviolet rays, causing almost no damage to materials.

- Unlike corona discharge and plasma methods, which generate dust due to electrode spatter, excimer irradiation enables clean processing.

- Excimer irradiation uses light from a flat lamp, so there is no unevenness in processing.

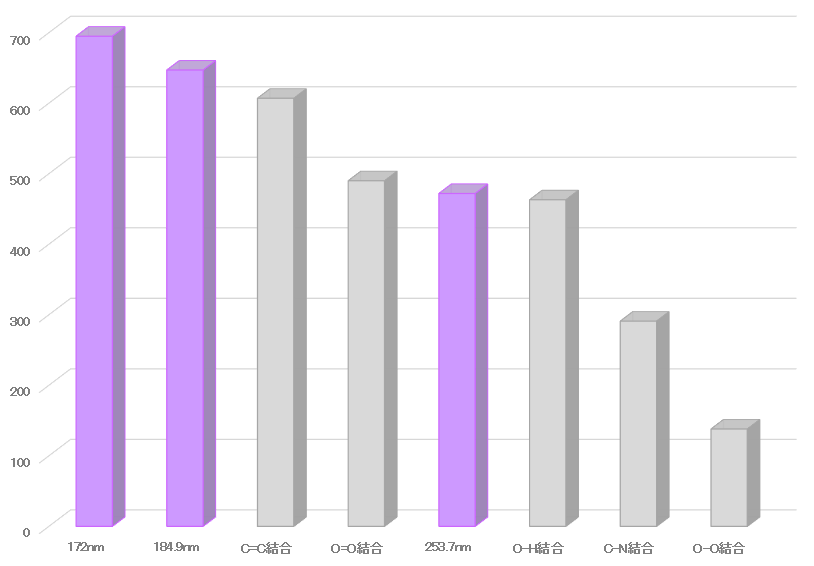

Wavelength 172nm Energy of excimer light

Scanning excimer irradiation equipment for R&D

It integrates an excimer irradiation unit with a main wavelength of 172nm, a stage for scanning, and an ozone decomposition device, and allows for simple and safe experiments of excimer surface modification using only a 100V power supply.

The scanning stage enables processing of a larger area than before. Integrated ozone decomposition unit eliminates the need for exhaust equipment, etc.

Example of customized excimer irradiation equipment

Scanning irradiation equipment for excimer irradiation unit.

Maximum material size is 400 × 800mm.

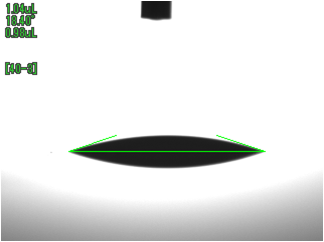

Example of modification by excimer irradiation equipment

Example of modification with high energy of 172nm excimer light