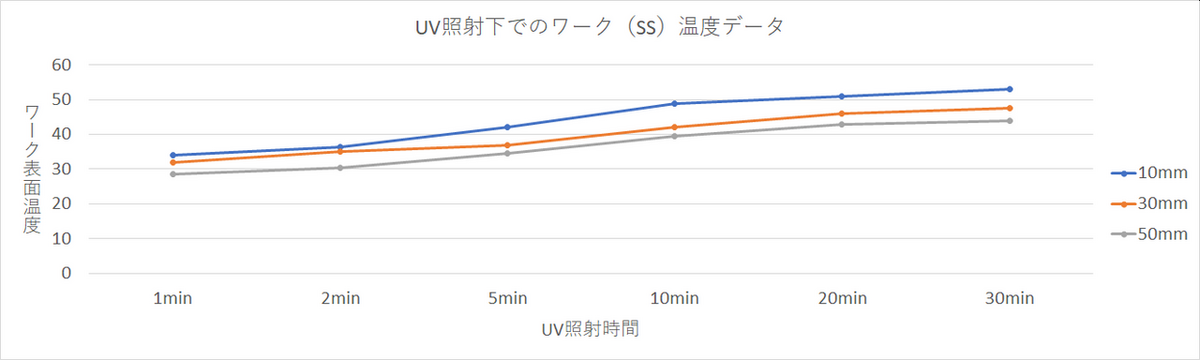

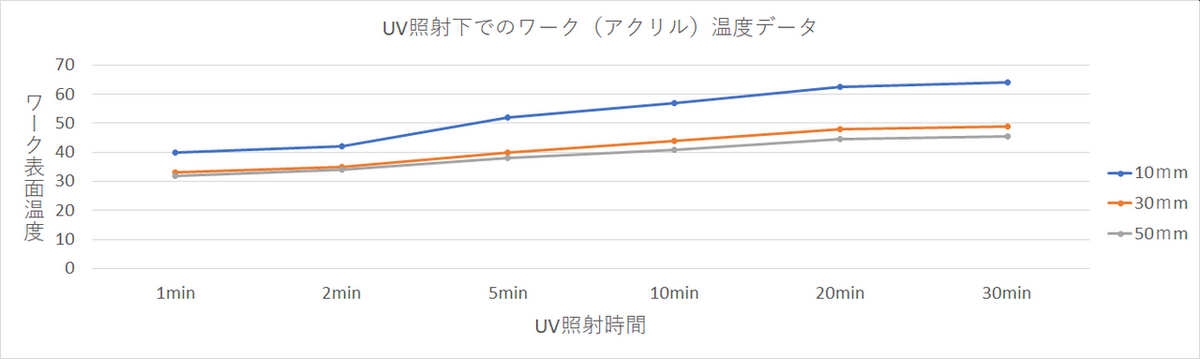

Temperature data of material under UV irradiation

There is a certain amount of heat emission from the surface of low-pressure mercury vapor lamps used in UV cleaning surface modification. The following is a brief summary of the relationship between irradiation time and temperature: compared to the high-pressure mercury vapor lamps used in UV curing, the temperature rise is suppressed.

| UV irradiation equipment | :ASM401N |

| Thermometers | :Laser Type Measurement Instrument made by CUSTOM corporation |

Materials: Iron plate (SS)

| Measurement Substrate | :SS 45100t1 (mm) |

| Measurement Point | :Center directly below lamp |

| Room temperature | :27℃ |

| Substrate temperature before starting treatment | :26℃ |

| Continuous irradiation time | ||||||

|---|---|---|---|---|---|---|

| Irradiation distance | 1min | 2min | 5min | 10min | 20min | 30min |

| 10mm | 34.0℃ | 36.5℃ | 42.0℃ | 49.0℃ | 51.0℃ | 53.0℃ |

| 30mm | 32.0℃ | 35.0℃ | 37.0℃ | 42.0℃ | 46.0℃ | 47.5℃ |

| 50mm | 28.5℃ | 30.5℃ | 34.5℃ | 39.5℃ | 43.0℃ | 44.0℃ |

Materials: Acrylic

| Measurement Substrate | :Acrylic plate 3080t2 (mm) |

| Measurement Point | :Center directly below lamp |

| Room temperature | :27℃ |

| Substrate temperature before starting treatment | :26℃ |

| Continuous irradiation time | ||||||

|---|---|---|---|---|---|---|

| Irradiation distance | 1min | 2min | 5min | 10min | 20min | 30min |

| 10mm | 40.0℃ | 42.0℃ | 52.0℃ | 57.0℃ | 62.5℃ | 64.0℃ |

| 30mm | 33.0℃ | 35.0℃ | 40.0℃ | 44.0℃ | 48.0℃ | 49.0℃ |

| 50mm | 32.0℃ | 34.0℃ | 38.0℃ | 41.0℃ | 44.5℃ | 45.5℃ |

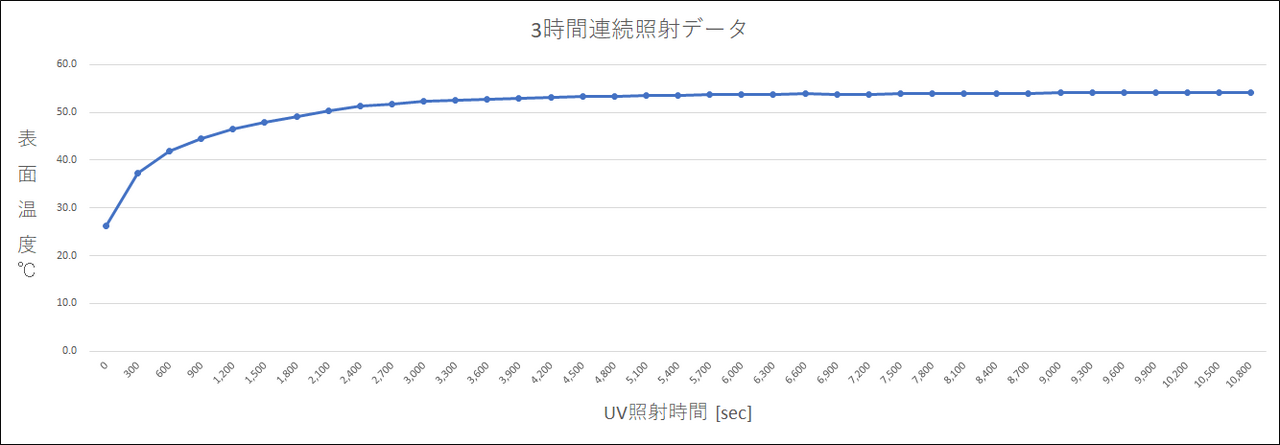

3 hours continuous irradiation data

The tip of a thermocouple is fixed to the surface of an acrylic plate (size: W20D20mm, t=2mm) using aluminum tape and irradiated for an extended period of time to measure changes in temperature.

| Equipment used | :ASM401N (S/N:212266) |

| Data Logger | :GL220(S/N:H20220753)made by Graphtec Corporation |

| Materials | :Acrylic plate |

| Irradiation distance | :30mm |

| Measurement conditions | :Room temperature:19.8℃ , Humidity:38% |

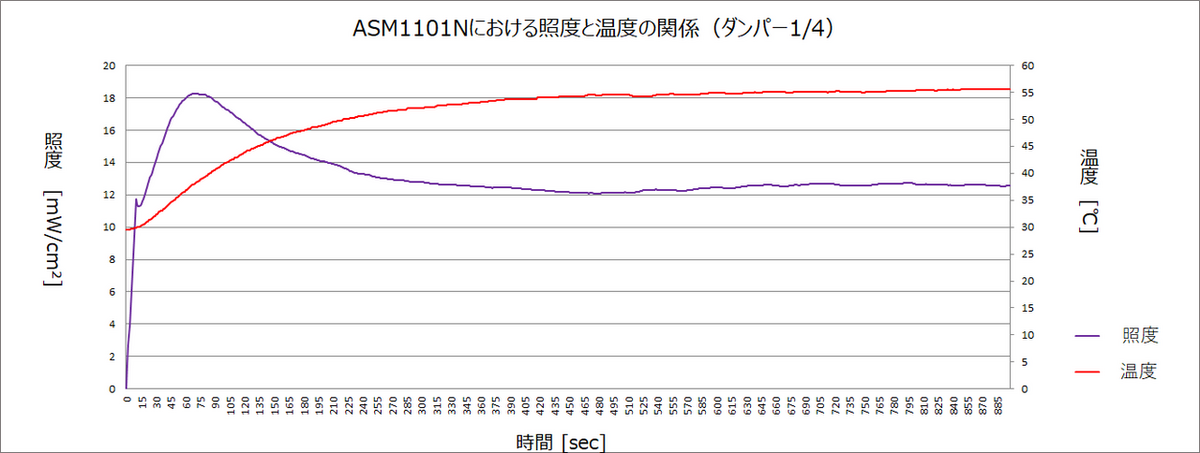

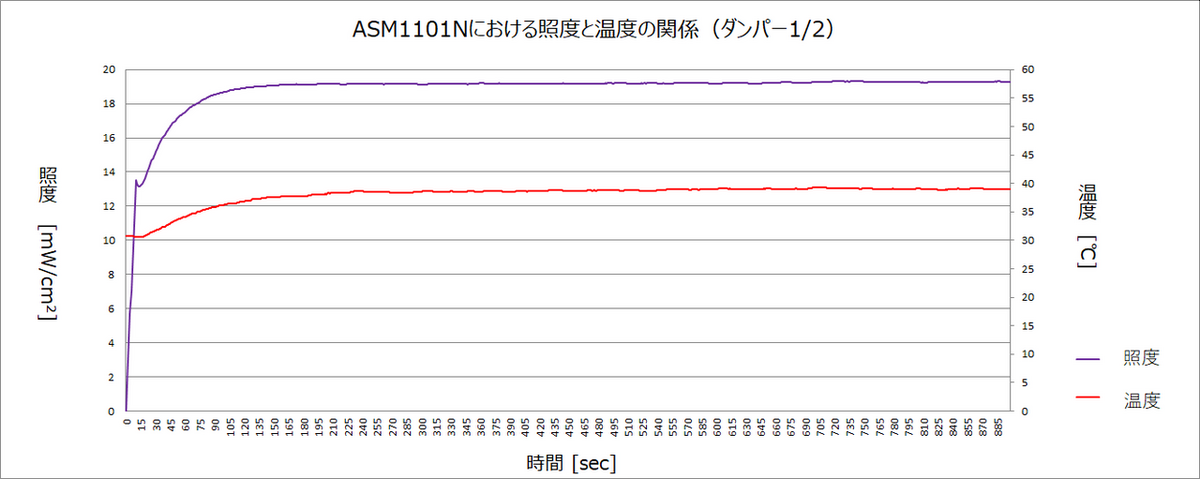

Lamp temperature data and illuminance change under UV irradiation

Measurement conditions

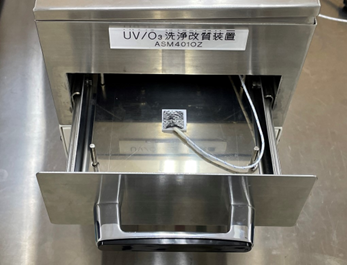

| UV irradiation equipment | :ASM1101N(S/N:212245) |

| Ozone decomposition equipment | :AOZ014 |

| Data Logger | :GL220(S/N:H20220753)made by Graphtec Corporation |

| Illuminometer | :UV-M03A made by ORC MANUFACTURING CO.,LTD. |

| Temperature measurement position | :110W low-pressure mercury vapor lamp electrode section fixed aluminum block surface temperature (left side of equipment) |

| UV measurement position | :Sensor surface to lamp surface distance 30mm |

| Measurement wavelength | :253.7nm |

| Room temperature | :25.0℃ |

Measurement Results

Table 1 shows that when the damper is opened 1/4 open, the lamp is not cooled enough due to insufficient intake of external air for cooling. As a result, the UV illuminance is stuck at 12 mW/cm2.

On the other hand, in Table 2, by increasing the damper opening to 1/2, sufficient external air is drawn in (approx. 1 m3/min), and by keeping the lamp terminal temperature around 40°C, the lamp outputs a higher illuminance than in Table 1.

Our UV irradiation equipment is designed with lamp temperature adjusted by air cooling to maintain optimum illuminance.

We are pleased to provide temperature measurement of the irradiated materials prior to the introduction of the equipment. Please feel free to contact us.