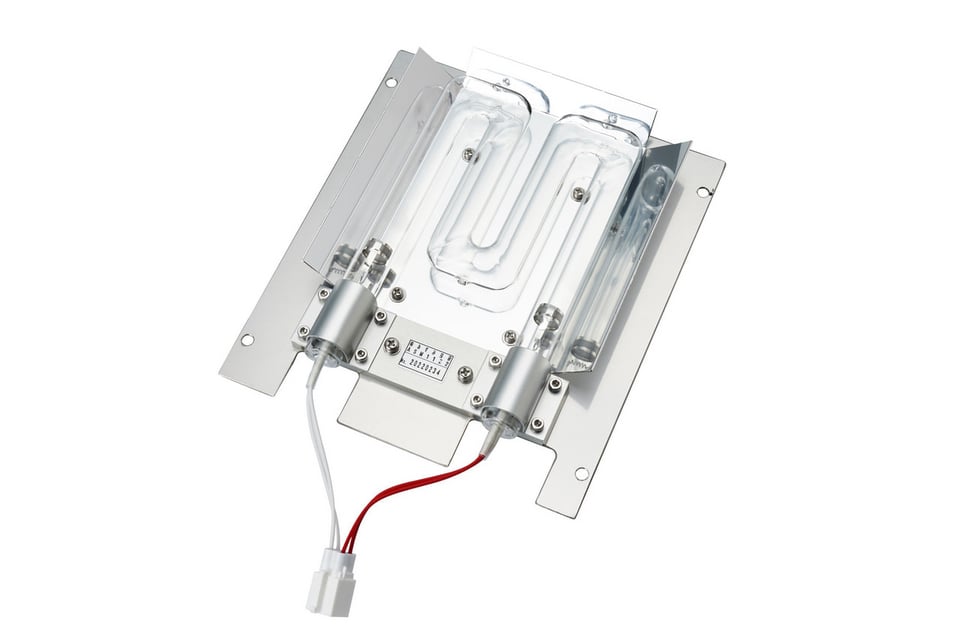

All devices use high-power, high-density grid-shaped hot cathode synthetic fused silica lamps, and are compact models designed for ease of use in the laboratory.

Fans and blowers for ozone exhaust and lamp cooling, as well as safety interlocks, are standard equipment, and the equipment is ready to use from the day it is received.

We also offer an abundant lineup of lamps and options that can be introduced into future-oriented mass-production equipment.

Features of our compact equipment for R&D

Adoption of high power and high density grid shape lamps.

Synthetic quartz and hot cathode are used. It is also ideal for setting conditions for future mass production.

Safety measure interlocks are standard

UV lamps automatically turn off when the door is opened. Standard on all models.

Fan/blower for ozone exhaust and lamp cooling is standard

No separate purchase is required.

Adjustable lamp distance

Various irradiation distances can be tried for conditioning.

Applications

Unlike plasma irradiation systems, there is no damage (electron or ion impact) to the device caused by the electric field. It is used for various applications, such as removal of organic matter, including ashing of photoresist and cleaning of silicon wafers, and improvement of adhesion by surface modification of resin and glass.

- Removal of organic film on glass and color filters for LCDs

- Improvement of adhesion of ITO film to glass and adhesion strength with insulating film

- Removal of organic film on lead frames, IC chips, etc., and hydrophilization

- Pretreatment of piezoelectric buzzers and ceramic LSIs for vapor deposition, improvement of component adhesion

- Adhesion improvement of connectors, switches, and cell phone exteriors

- Cleaning of silicon, compound semiconductors, crystals, ITO films, lenses, etc.