We manufacture compact tabletop UV ozone cleaning and reforming equipment equipped with low-pressure mercury lamps with UV main wavelengths of 184.9 nm and 253.7 nm.

UV light at 184.9 nm and 253.7 nm can remove organic contamination from various types of surfaces.

Our UV ozone cleaning and modification equipment cleans silicon, quartz, gold, stainless steel, copper, nickel, aluminum, gallium arsenide, alumina, glass, ITO, mica, sapphire, ceramic, platinum substrates, LCD and LED displays, AFM probes and chips, SEM and TEM samples, and more The surface of most materials can be cleaned without chemicals, easily, inexpensively, and quickly without damaging the device, in a matter of minutes.

Types and characteristics of low-pressure mercury lamps

There are two types of low-pressure mercury lamps: hot cathode and cold cathode. They are divided by the electron emission method, with cold cathode having lower luminous efficiency than hot cathode. The cold cathode type has a low unit density and low UV intensity, which limits its use beyond actual equipment, reflecting test results, and is considered unsuitable for cleaning and reforming applications.

Our low-pressure mercury lamps use a hot cathode type.

| Hot cathode type | Cold cathode type | |

| Lamp Wattage (unit density) | High | Low |

| UV intensity (output) | High (tens of mW) | Low (several mW) |

| Lamp life (under continuous lighting conditions) | 6,000 hours | 10,000 hours |

| Production applications | Numerous Achievements | Small size only |

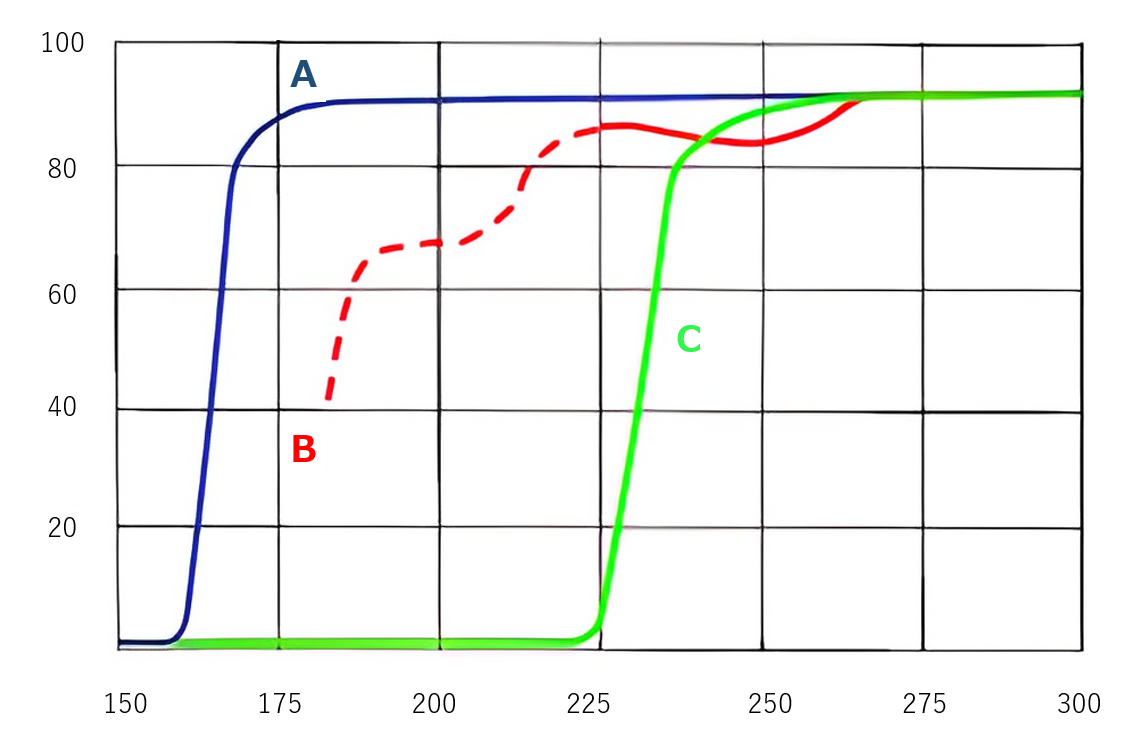

Types of Quartz Materials

The type of quartz glass used in the lamps changes the UV transmission characteristics and lamp performance. For cleaning and modification applications, synthetic quartz low-pressure mercury vapor lamps that efficiently transmit the short wavelength of 185 nm should be used.

A.Synthetic quartz・・・High-performance quartz with high transparency

B.Natural quartz・・・Transmission around 185nm is about 50%.

C.Fused quartz・・・Cutting wavelengths below 220nm

Our low-pressure mercury lamps are made of synthetic quartz.

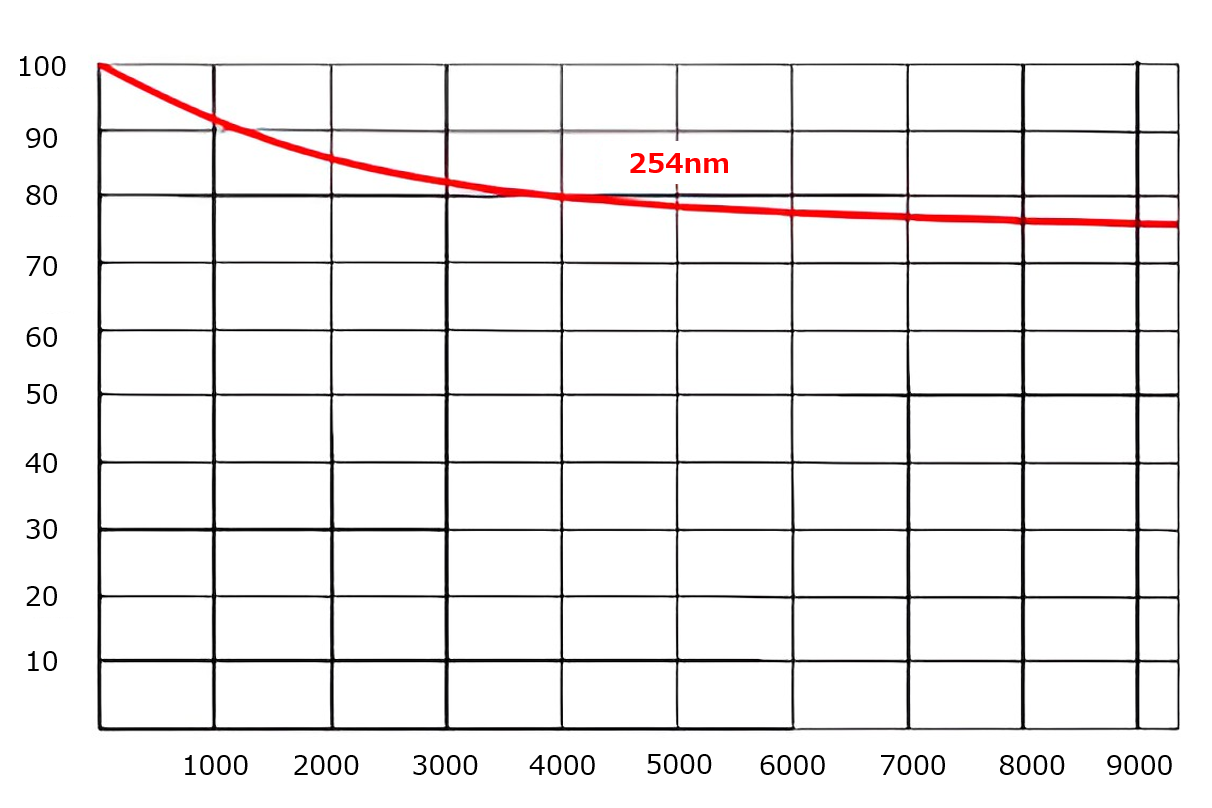

Low-pressure mercury lamp life

As low-pressure mercury lamps continue to be lit (used), the amount of impure gas in the light-emitting tube increases, contaminating the tube wall and significantly decreasing the UV irradiance maintenance rate. We have developed a long-life series of lamps that can maintain high UV irradiance at the end of their life by improving the lamps to control these factors. The use of these lamps will be effective in all aspects, such as increasing throughput, reducing the number of lamps used, and enabling stable production control.

What is UV Irradiation System

Ultraviolet (UV) light has a relatively high photon energy and, depending on the wavelength emitted by the lamp, is used in many applications, including metabolism promotion in living organisms, removal of organic matter, surface cleaning, surface modification, sterilization and purification, ozone deodorization and sterilization, curing, adhesion, and drying.

A familiar example is black light.

The main wavelength is 300 nm to 400 nm, and it is used in fields such as medicine, biology, and art appraisal.

For surface cleaning and surface modification applications, low-pressure mercury lamps with wavelengths of 184.9 nm and 253.7 nm are used, and the equipment itself is called UV cleaner (UV cleaner, UV ozone cleaner), UV cleaning equipment, UV surface modification equipment (UV surface modification), etc.

For sterilization and cleaning applications, a wavelength of 254 nm, which acts on and damages DNA in cells, is used, and ozone is generated to clean water and deodorize it.

For curing, bonding, and drying applications, high-pressure mercury lamps and metal halide lamps that output a wavelength range of 365 nm and other wavelengths are used, and the equipment is called ultraviolet curing equipment (UV curing equipment), ultraviolet curing (UV curing), and ultraviolet drying equipment (UV drying equipment), among other names.

What is generally referred to as ultraviolet irradiation equipment (UV irradiation equipment) is divided into various uses depending on the type of ultraviolet lamp (UV lamp) and the wavelength emitted.